In order to ensure that water is stored and protected under more reliable and healthier conditions; odor-free, non-germ-producing, fully hygienic water storage tanks are produced with modular parts in desired tonnage (m3) using (ST 37) hot dip galvanized material.

Capacity Range: 1 -1000 M3

Material : Hot dip galvanized

DURABILITY

Modules are strengthen with high pressure presses and cold forming.

HYGIENE

All parts of modular storage tanks are produced in accordance with the hygiene conditions. In no way algae and bacteria occurs in stainless hot dip galvanized water tanks.

MAINTENANCE AND REPAIR

Maintenance and repair is very easy. Parts can be replaced independently whenever needed.

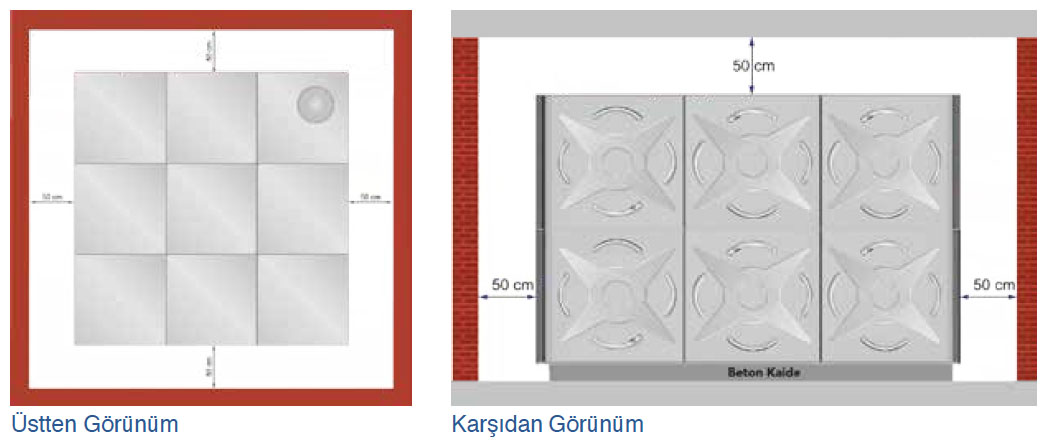

TRANSPORTATION AND INSTALLATION

Sectional water tanks can be easily mounted to any desired location in module pieces. Assembly is done with special bolt tightening machines. It can be easily dismantled and mounted to another place when desired. When place is available, the size of the tank can be enlarged by increasing the numbers of modules even after the installation is done. Modules are easily transported through narrow spaces to where installation is done.

Can be easily installed to on any preferred floor, high platforms, the roof, towers and existing buildings.

1. Water input

2. Sediment filter

3. Optionally

a) Normal valve + float

b) Motor valve with top-level electrode remote operated

4. Top level electrode: It controls the motorized valve and closes the valve when the tank is full.

5. Tank top manhole cover

6. Lower-level electrode: Automatically stops the booster motor when the tank runs out of water. (does not when empty)

7. Tank water level indicator

8. Overflow pipe

9. Stairs

10. Tank modules are connected to each other with bolt nuts

11. Between the modules are sealed with rubber seal and special silicon

12. Bottom of the tank is covered with bolt seal

13. Tank discharge valve

14. Tank output valve

15. Ultra violet (UV) germ killing device

16. Water softening output. Purifies the water from the calves such as lime, Ca and Mg.

17. Activated carbon unit: It removes harmful gases from the water like chlorine etc.

18. Booster motor

19. Underfloor concrete or steel pedestal