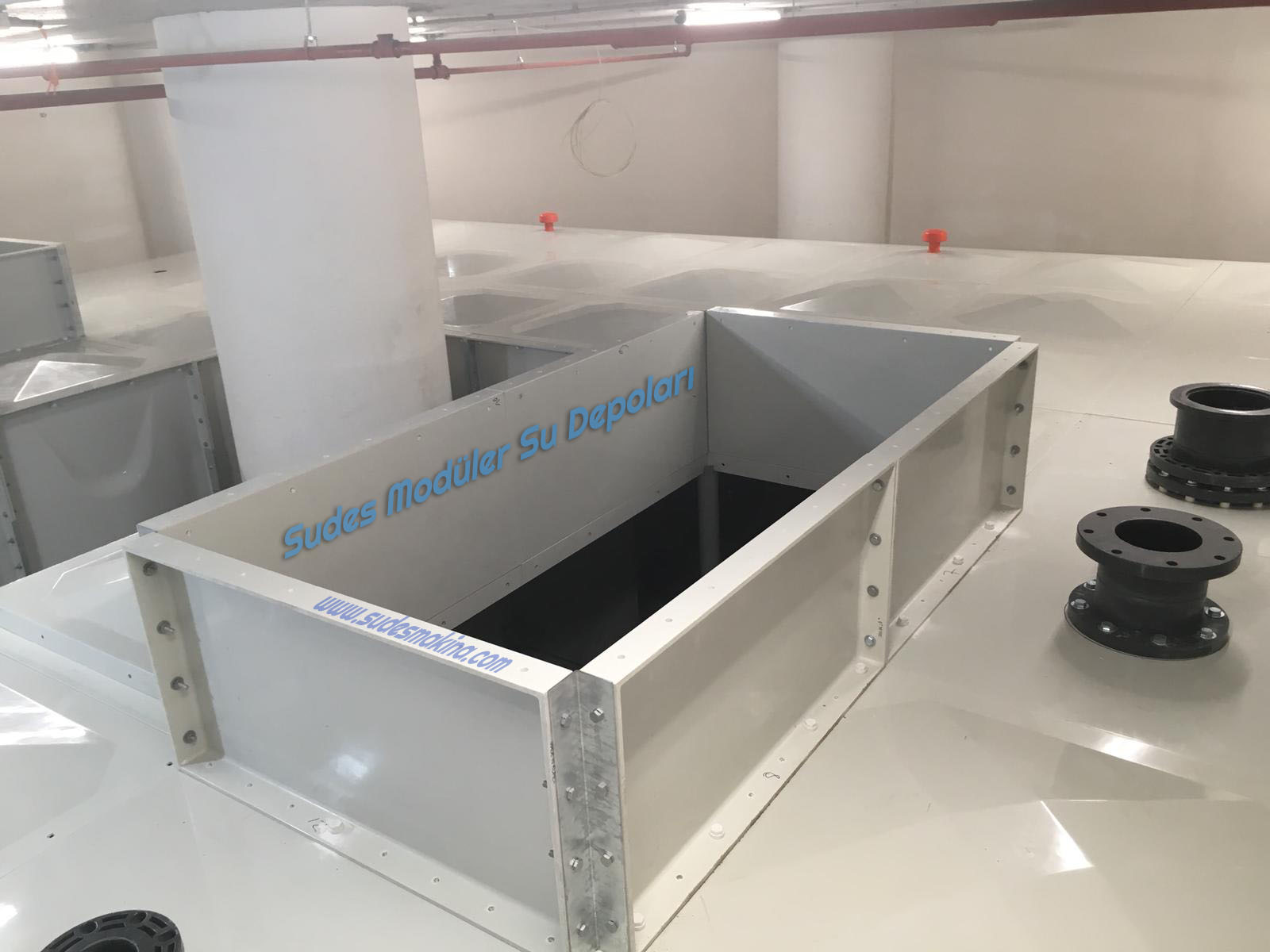

Capacity Range: 1-5000 m³

What is GRP (Glass-fiber Reinforced Polyester)?

GRP Sectional water tanks are produced by high pressure and high temperature curing of hot pressed sheets consists of unsaturated polyester resin which is reinforced with cropped glass fiber. Panels are manufactured in molds are heated to 150℃ degree in heavy weight presses. Thanks to the mold and manufacturing technology used, both sides of the produced panels are smooth, completely cured and durable.

Sudes GRP panels come with world-wide recognized The Water Regulation Advisory Scheme (WRAS) certificate. In addition, it complies with food regulations reported by Turkish Standard Institution (TSE). It is resistant to UV rays and does not allow moss to form in the tank as it is not transparent.

THERMAL INSULATION

GRP Sectional tanks are coated with polyurethane foam to provide thermal insulation. The insulation material used does not contain CFC and HCFC. It does not harm the nature.

DURABILITY

The GRP tanks use cropped glass fiber and polyester resin as its raw material. GRP panels are produced by hot pressing which makes them durable and long lasting.

HIGH STRENGTH

GRP panels are produced by pressing the hot mold in heavy weight presses. Due to its form, the panels are resistant to high pressure. GRP tanks are more robust than their alternatives. They are resistant to Ultra Violet (UV) rays. Extra heat insulation can be applied on the panels.

OPEN FIELD USE

GRP tanks can be installed in open areas as their heat conduction is low and they are resistant to UV lights.

HEAT AND LIGHT INSULATION

GRP tanks are opaque, so they do not allow the formation of algae.

The panels forming the modular water tanks can be isolated and used as a hot / cold water tank in all-weather conditions.

HYGIENE

Compliance with food regulations has been proven by laboratory reports.